What are Chase Machines?

Imagine a machine that can cut, weld, and drill metal with incredible precision, all in one go. That’s essentially what a chase machine is!

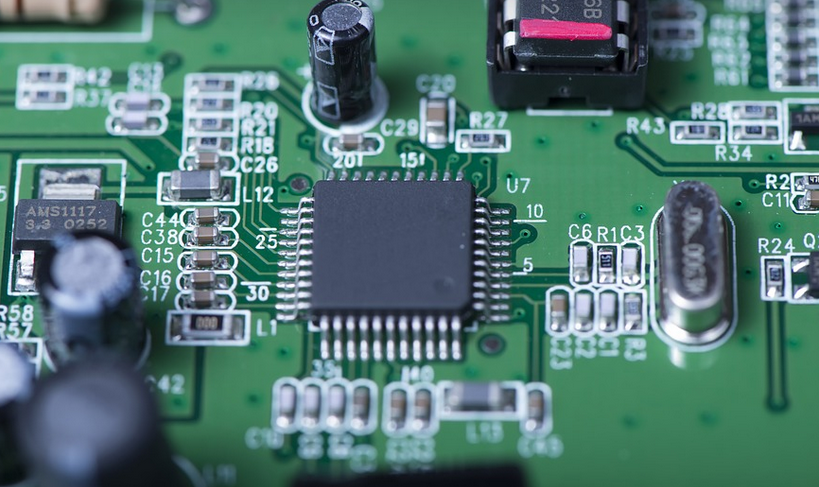

Chase machines, also known as CNC (Computer Numerical Control) machines, have revolutionized manufacturing processes across various industries. Instead of manually operating tools like lathes or milling machines, these advanced systems utilize computer programs to create intricate shapes and patterns in metal.

These machines are incredibly precise, allowing for the creation of complex geometries with high-quality finishes. They often feature rotary axes, linear axes, and other kinematic elements, all controlled by a sophisticated software system. This combination allows them to perform repetitive tasks with accuracy, speed, and consistency, resulting in high-volume production.

The heart of a chase machine lies in its control system. A computer program controls every movement, enabling intricate and complex machining operations. This software is programmed to follow specific instructions based on the desired shape or design. The control system also monitors real-time feedback from sensors, ensuring the process stays accurate and predictable.

These machines are particularly valuable for industries that produce parts with tight tolerances. Think about creating small screws or intricate gears, or even highly customized components for automobiles and aerospace engineering. Chase machines excel in these areas due to their precision control and ability to perform multiple operations within the same machine.

The versatility of chase machines extends beyond simple metal-working. They can be used for tasks like plastic molding, welding, and even electronic fabrication. This adaptability makes them valuable contributors across a broad spectrum of industries.

Exploring Different Types of Chase Machines

While the fundamental concept remains similar, there are several different types of chase machines that cater to specific applications and manufacturing needs:

– **CNC Lathes:** These are ideal for turning and shaping metal components. Their rotating spindle allows them to create round objects, grooves, or cylinders with exceptional precision.

– **CNC Milling Machines:** These machines utilize a multi-axis system to precisely carve out shapes from solid blocks of metal. They’re perfect for creating intricate designs and complex geometries.

– **3D CNC Machines:** These machines allow for the creation of three-dimensional objects directly from CAD models. The machine moves in multiple axes simultaneously, working on different planes to build up a finished part.

– **Laser Cutting Machines:** These machines use lasers to precisely cut and engrave materials like wood, metal, and plastic. They’re often used for intricate designs where precision and speed are critical.

– **Waterjet Cutters:** These machines use high-pressure jets of water mixed with abrasive particles to cut through various materials, including metals, plastics, and composites. Their ability to cut through thick materials makes them ideal for projects requiring deep cuts.

Why Chase Machines are Essential for Modern Manufacturing

The benefits of using chase machine technology in modern manufacturing are undeniable:

– **Increased Precision:** Chase machines offer unmatched accuracy, ensuring parts meet the required specifications even down to the smallest detail. This precision translates to fewer rework and waste, saving both time and money.

– **Improved Efficiency:** By automating repetitive tasks, chase machines significantly increase production speeds and reduce overall manufacturing times. They streamline work processes, leading to better productivity.

– **Enhanced Quality Control:** These machines offer consistent quality control through automated inspection and feedback mechanisms. This eliminates human error and ensures higher product standards across batches.

– **Cost Savings:** By reducing the need for manual labor, chase machines often lead to significant cost savings in the long run. The automation of production processes contributes to a more efficient factory layout and reduced operational costs.

Furthermore, chase machines contribute to sustainability by enabling optimized material usage and minimizing scrap. These machines allow manufacturers to produce parts with fewer waste materials, leading to smaller environmental impact.

The Future of Chase Machine Engineering

As technology continues to evolve, the future of chase machine engineering is promising:

– **Artificial Intelligence (AI) Integration:** Advancements in AI will allow for even more precise control over machines and greater automation. This can lead to faster production cycles, improved quality, and reduced human error.

– **Collaborative Robots (Cobots):** The integration of collaborative robots on chase machines will further enhance efficiency and safety. Cobots can be programmed to work alongside humans, allowing for a safer, more productive manufacturing environment.

– **Augmented Reality (AR) & Virtual Reality (VR):** AR and VR experience offers new perspectives for design, troubleshooting, and training. These technologies can help engineers visualize complex designs, simulate production processes, and train workforce in realistic virtual work environments.

– **Sustainable Manufacturing:** Chase machines will continue to play a vital role in sustainable manufacturing practices. They’ll enable the creation of more efficient and eco-friendly products with reduced material waste, further contributing to environmental responsibility.